Automated solutions

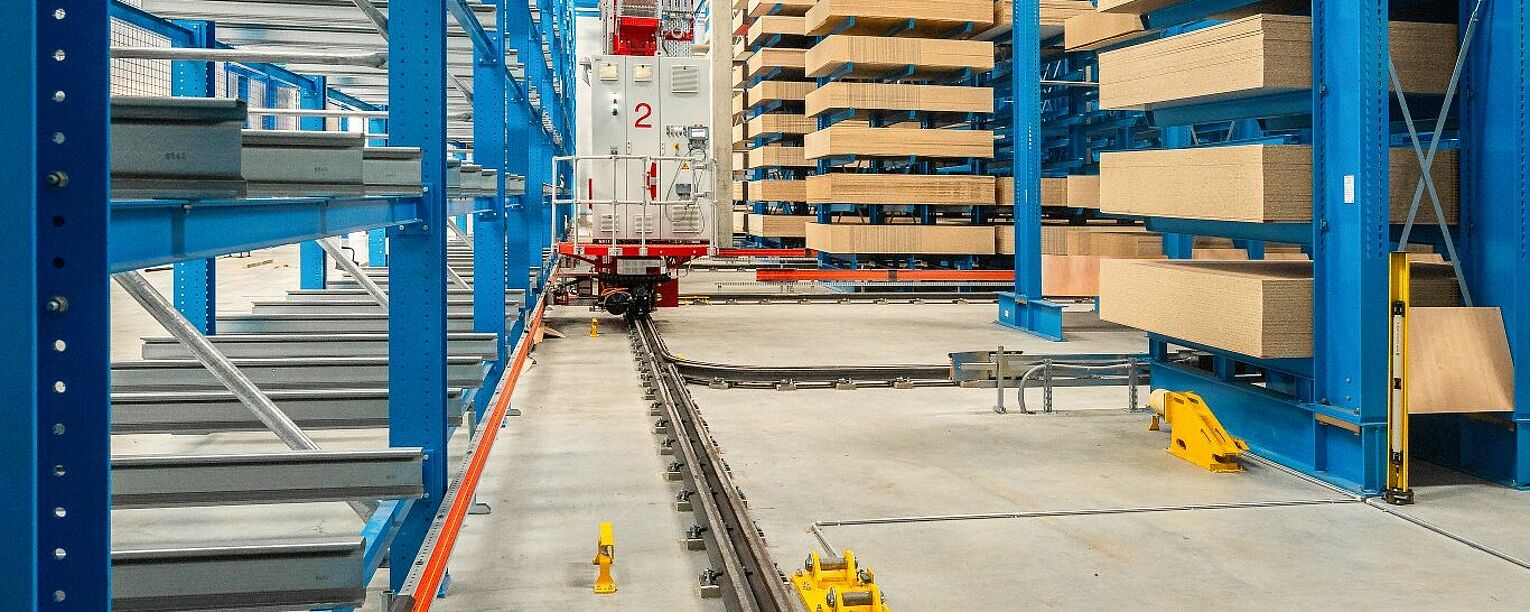

In an automated storage system, the entire material flow is controlled by computers and carried out with special machines such as stacker cranes. No employees are needed for storage and retrieval. The racking systems for the automated warehouse must be configured for the various material flow tasks and the goods to be stored. Almost all cantilever racking systems can be expanded or converted into an automatic racking system with the help of software and the corresponding storage and retrieval machines.

The robust cantilever racking forms the basis. This is where the goods are stored that are to be recorded and moved under computer control. Appropriate warehouse software controls all warehouse processes such as storage and retrieval, order picking and inventory.

The optimal conveyor technology is the third link in the chain of racking automation. The selection of the right storage and retrieval machine is one of the decisive factors for a smooth automatic process. All three components - cantilever racking, stacker crane and warehouse software - are coordinated with each other.

Automatic storage systems are increasingly found in the wood and metal trade, where long goods are picked. The processes in the warehouse such as storage and retrieval, preparation for dispatch

Features of automatic storage systems:

- Speed in order-picking processes

- Energy and cost savings in the warehouse

- Can be used in 24-hour operation

- Reduction of personnel costs

![[Translate "Ireland"] Automatic Cantilever racking](/fileadmin/_processed_/c/2/csm_cantilever_racking_automated-storage_01_c04049c301.jpg)